The Furibee F36 transmitter with its internal antenna doesn’t have much range. This is fine with line of sight (LOS) flying but with first-person view (FPV) flying, you’d probably want a bit more range. We can drill a hole through the casing and thread the antenna through and out of it which can increase range. But why stop there? Let’s install an external antenna.

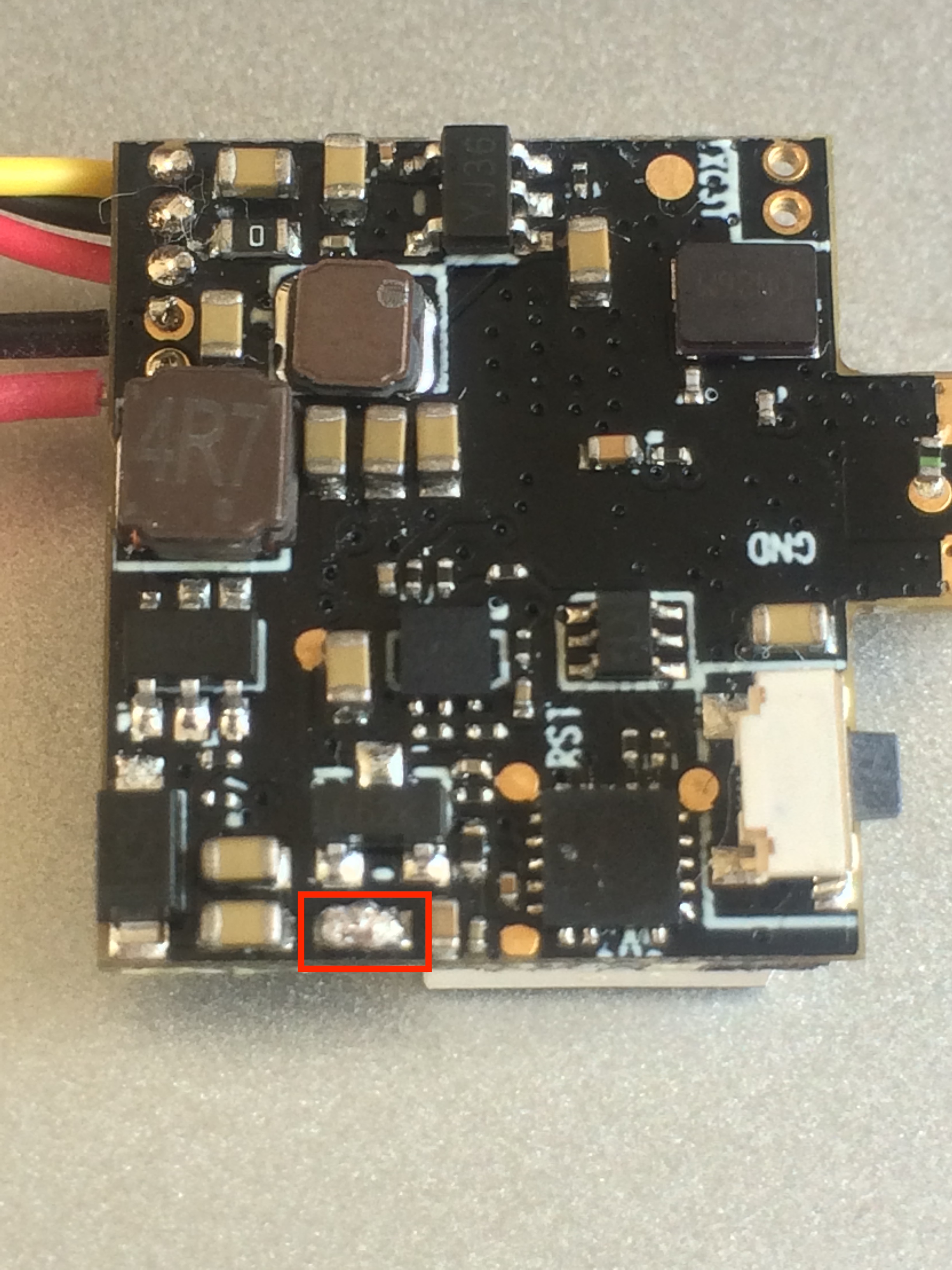

And just like that the VTX03 lit up back to life!

And just like that the VTX03 lit up back to life!