A Rakonheli 66mm brushless whoop is an awesome aircraft. But sometimes you just gotta have extra ooomph, like maybe for carrying a Turbowing Cyclops 3 HD camera. So I build a bigger, more powerful version: The Rakonheli 76mm brushless whoop.Parts and Equipment

A Rakonheli 66mm brushless whoop is an awesome aircraft. But sometimes you just gotta have extra ooomph, like maybe for carrying a Turbowing Cyclops 3 HD camera. So I build a bigger, more powerful version: The Rakonheli 76mm brushless whoop.Parts and Equipment

For this build, I used the following:

- Rakonheli 76mm Brushless Whoop frame

- Rakonheli 40mm 3-blade clear propellers - 1.5mm shaft diameter

- Boldclash BWhoop B06 Canopy

- Super_S F4 Flight Controller with Super_S 4-In-1 6A ESC

- Flysky RX2A Pro Receiver

- Turbowing Cyclops 2 5.8G 48CH 25mW VTX

- Kingkong 800TVL 150 degree FOV camera

- Racerstar BR01103 Racing Edition 10000KV Motors

- Soldering iron

- Soldering wire

- Desoldering pump

- Flux

- Wire snips

- Double-sided tape

Build Procedure

- Assemble the frame. There are lots of tiny screws of different sizes. A vernier caliper will come in handy

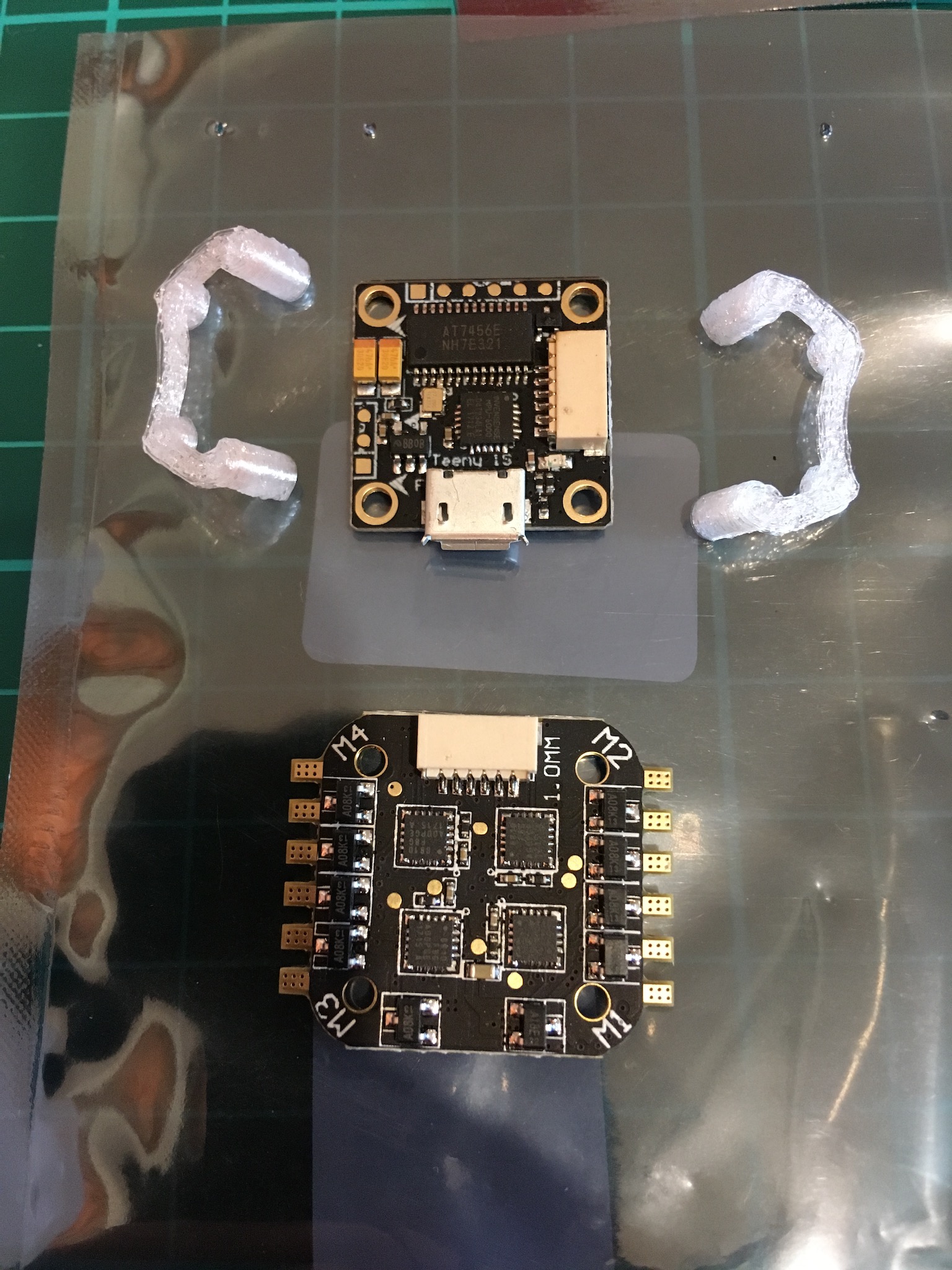

Lay out the FC and the ESC. Ignore the standoffs and screws included in the FC and ESC package and use the screws included with the Rakonheli frame kit.

Lay out the FC and the ESC. Ignore the standoffs and screws included in the FC and ESC package and use the screws included with the Rakonheli frame kit.

Note the FC is not facing forward. This is so that the USB port will be accessible. We will need to configure orientation to -90 yaw in Betaflight.Â

Note the FC is not facing forward. This is so that the USB port will be accessible. We will need to configure orientation to -90 yaw in Betaflight. - Plug in the FC-to-ESC harness and assemble the FC and ESC stack.

When mounting the ESC and FC together using the metal screws, if the screws touch, it may cause a short. Best to use nylon screws. If you have to use the metal screws, shorten them. Finally use multitester to see that there’s no continuity on the corresponding screws of the FC and ESC.

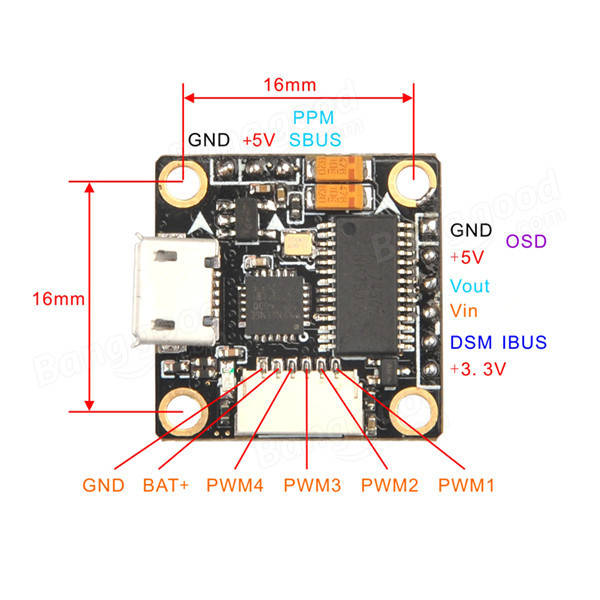

When mounting the ESC and FC together using the metal screws, if the screws touch, it may cause a short. Best to use nylon screws. If you have to use the metal screws, shorten them. Finally use multitester to see that there’s no continuity on the corresponding screws of the FC and ESC. - Review pad layout

Mount the motors. Ignore the screws included with the Rakonheli frame kit (which are too small) and use the screws included with the motor package.

Mount the motors. Ignore the screws included with the Rakonheli frame kit (which are too small) and use the screws included with the motor package.

Mount the stack onto the frame

Mount the stack onto the frame

Pre-tin the battery pads and ESC pads

Pre-tin the battery pads and ESC pads - Solder in the battery pigtail to the battery pads and the motors wires to the ESC pads

This  is probably the hardest part of the build. You will need to trim the motor wires and strip the ends. Then, set your iron to 400°C, add some solder to the tip and  burn off the copper wire’s coating. Finally, solder with your iron set to 350°C and use flux.

This  is probably the hardest part of the build. You will need to trim the motor wires and strip the ends. Then, set your iron to 400°C, add some solder to the tip and  burn off the copper wire’s coating. Finally, solder with your iron set to 350°C and use flux. - Solder the RX, VTX, and camera wires to the FC.

Once all soldering is done, check continuity between B+ and B- with a multitester. There should be NO continuity.

Once all soldering is done, check continuity between B+ and B- with a multitester. There should be NO continuity. - Cross your fingers, plug-in the battery and check for magic smoke

- Install the canopy and props. Note that the canopy needs some trimming to properly fit.

Done!

Done!